Gravity Casting and Low Pressure Casting

The gravity and low pressure castings are strongly recomended when high mechanical properties and quite complex shapes are the primary requirements. Compi foundry experience begun in 1997 and it is now a core business. Casting process have been made in these years extremely reliable.

Finishing

The aluminium castings may need several treatment before being ready for machining. Therefore Compi can offer a full range of post-casting processes like Sand de-coring, Heat treatments (T6, Ageing, etc.), Sandblasting, De-burring, etc. They are all sized on the casting capacity and available at customer request.

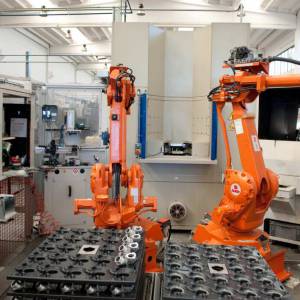

Capacity

Compi works with both manual and automatic (robotized) casting lines. The actual capacity is: 2400Kg/day for the gravity lines, 9000Kg/day for the low pressure castings.

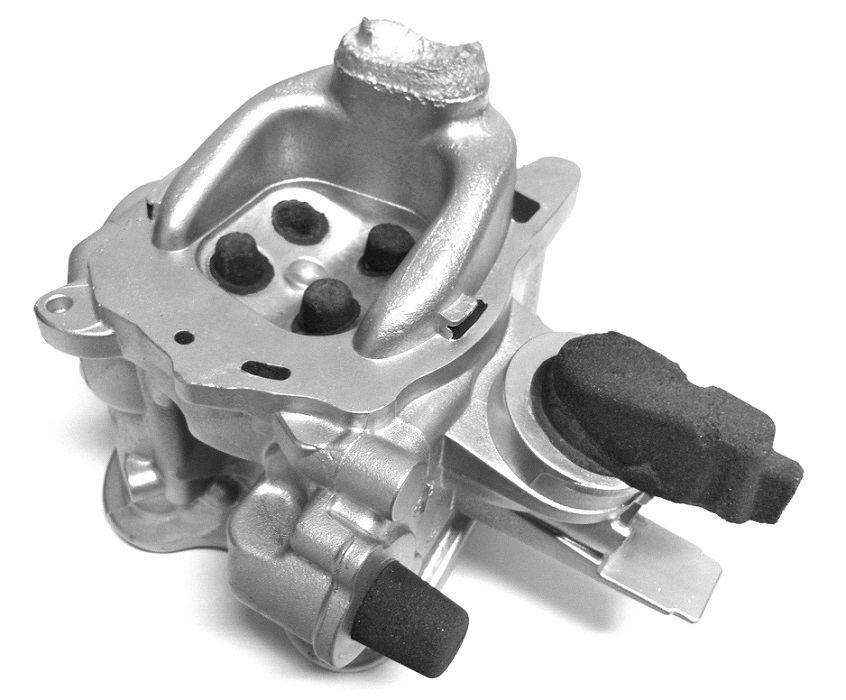

Features

- Internal sand core manufacturing;

- A wide battery of electric ovens gives a better quality alloy and the possibility to deal with different alloys at the same time; On the other hand, the gas oven guarantees high volumes capacity.

- An associated tool maker, C.A. Stampi, guarantees a synergy in co-design, feasibility studies and tool supplies with a great benefit for the customer;

- Availability of a casting simulator (QuikCAST)