This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Info line: +39 0872 50841

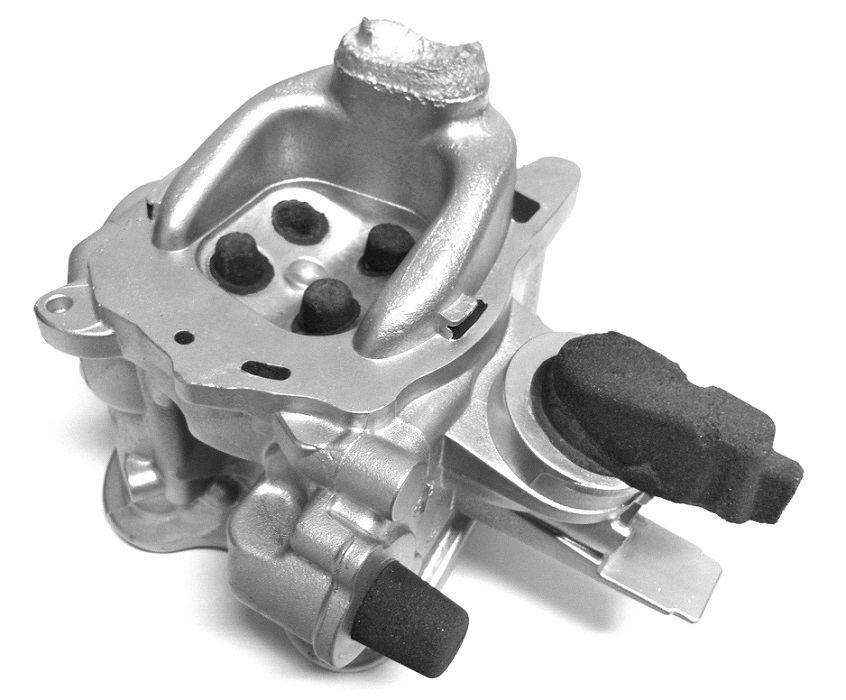

Hot Box:

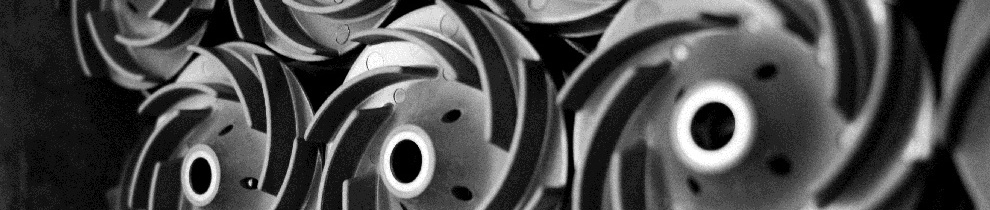

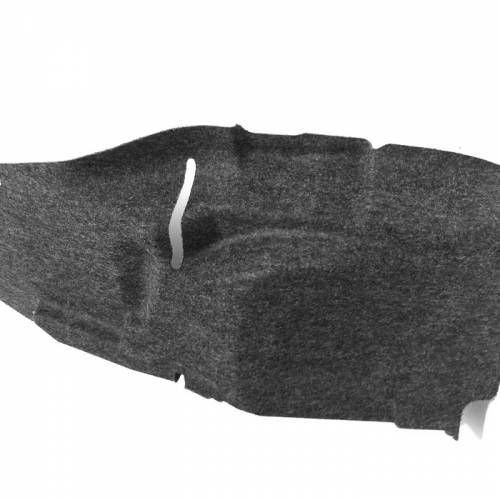

The majority of the sand we use is French-Silicae with low grain size. Due to this, our sand cores, formed in Hot Box, have a very low roughness without any additional coating for the critical areas. The granulometry over the resin quantity ratio has been carefully tested and optimized in order to obtain the best from both the stiffness and the after-casting removability points of view. Such a “ratio” is the reason why Compi chose and keep in use different typologies of sand, depending of what required by the casting to be obtained.

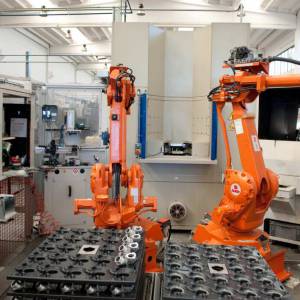

Capacity:

Compi use manual Sand core Shooters for the low volume projects and fully robotized isles for the high series sand cores. The whole core manufacturing department has a proportioned capacity to the one offered by the foundry; it can produce about 8.000 sand cores a day.

Features:

Starting from the functional request given by the customer, Compi autonomously develop the sand core design. In many cases, the sand cores need to be glued (so assembled) or to be used for external surfaces instead of the steel shell (when consistent draft angles are involved).