This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

- Info line: +39 0872 50841

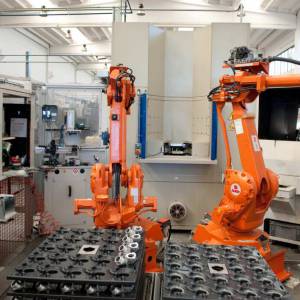

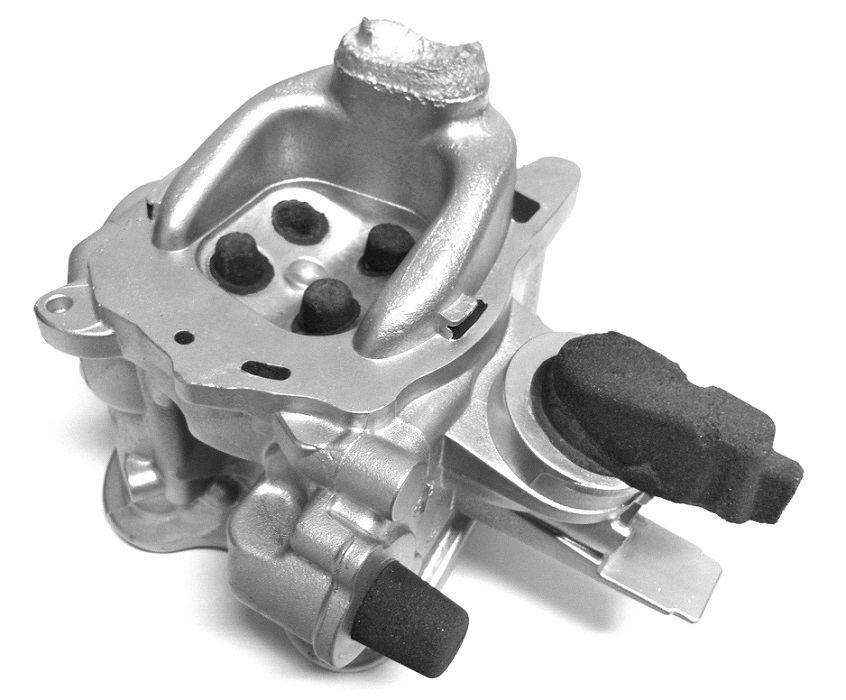

CNC:

Compi have at disposal around 40 CNC Mazak machines. A half of them are double spindle Turning Machines and the other half is 4-axis Milling Machines. 80% of our machines is integrated in robotized isles, for automatic feeding and handling of parts. Such isles keep an high flexibility because we can convert and re-customize on our own, when the volume of projects require a switch (change of the automation level of production).

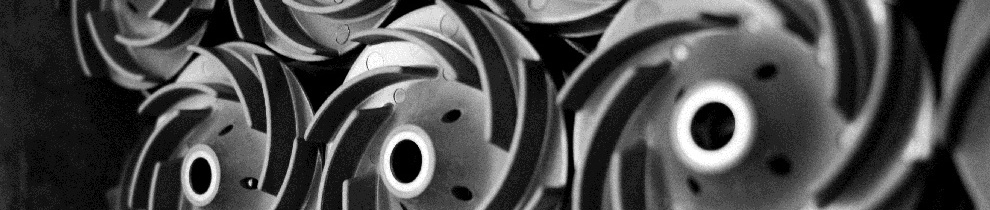

Materials:

Compi strategically aim to machine their own castings, therefore the principal material we work with is Aluminium. Anyway, working for years on the Turbochargers first equipment supply, Compi experienced the machining of components in cast iron, steel, INOX, etc./p>

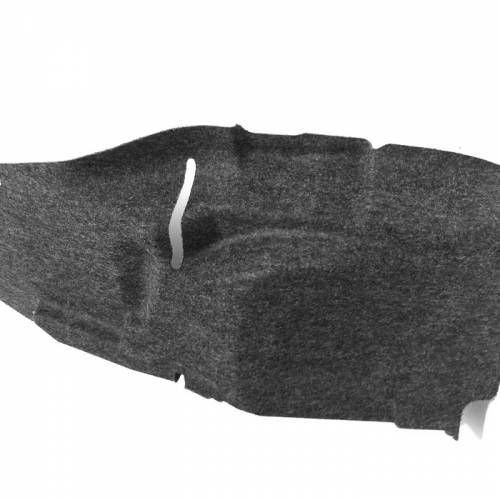

Finishing:

The finishing process after the machining phase, can consistently vary depending on customer requirements. Averagely speaking, the part has to be carefully de-burred, washed accordingly with the prescribed cleanliness standards, assembled (pins or small components are often included), leak tested (in pressurized air environment) and finally visually inspected in every aspect by specialized operators. For the high series project, Compi implement all the foreseen finishing steps in a full automatized isle.

Features:

All the necessary production equipment, from mold to fixtures, and all the elements to customize the automatic isles are designed and manufactured by C.A. Stampi, an associated toolmaker.